Optimize Your PCB Test Fixture Design with Flexible Test

The efficiency and precision of Printed Circuit Board (PCB) test fixtures play a pivotal role in ensuring the reliability of electronic devices. As technology advances, the demand for more intricate and compact PCBs grows, necessitating innovative and adaptable testing solutions. This is where Flexible Test emerges as a game-changer, offering a comprehensive suite of tools and expertise to optimize your PCB test fixture design.

The Challenges of PCB Testing

- Connector Vulnerabilities: The Achilles’ Heel of Testing

- Connectors play a pivotal role in PCB testing, serving as the crucial link between the Device Under Test (DUT) and the testing equipment. Traditional connectors, especially the widely used Zero Insertion Force (ZIF) connectors, exhibit vulnerabilities that can compromise the reliability of testing setups. Wear and tear on these connectors, induced by repeated testing cycles, can lead to a host of issues, ranging from intermittent connectivity to outright failure. Flexible Test confronts this challenge head-on by offering engineered contacts designed to withstand thousands of cycles, providing a robust and dependable solution to connector vulnerabilities.

- The Pitfall of Frequent Replacements

- Frequent replacements of connectors can become a persistent headache. The traditional wear-and-tear experienced by connectors, especially in high-frequency testing scenarios, can result in a constant cycle of replacements. This not only introduces downtime into the testing process but also escalates maintenance costs. Flexible Test’s approach to durable engineering aims to break this cycle, providing fixtures constructed with robust materials that endure thousands of testing cycles. This commitment to longevity not only reduces the need for constant replacements but also contributes to a significant reduction in maintenance expenses.

- Intricate Configurations: A Barrier to Efficiency

- As devices shrink in size and complexity, the need for intricate configurations in traditional PCB testing setups can become a significant barrier to efficiency. Complexity often translates to time-consuming setup procedures, demanding meticulous adjustments and alignments. Flexible Test revolutionizes this aspect by offering drop-in solutions that seamlessly bridge the gap between the DUT and test equipment. The result is a straightforward setup that eliminates the need for complex configurations or extensive adjustments, streamlining the testing process and enhancing overall efficiency.

- Escalating Maintenance Costs: The Silent Disruptor

- Maintenance costs can quietly escalate as a consequence of connector vulnerabilities, frequent replacements, and intricate configurations. The traditional paradigm often necessitates a delicate balance between maintaining testing equipment, replacing connectors, and ensuring the reliability of the overall setup. Flexible Test’s commitment to durable engineering, efficient setup solutions, and expert support is not merely a response to these challenges but a proactive approach to minimizing maintenance costs. By addressing the root causes of these challenges, Flexible Test aims to provide a testing environment that is not only reliable and efficient but also sustainable in the long run.

Flexible Test offers solutions that go beyond conventional approaches. The future of PCB testing lies in a paradigm shift, one that prioritizes durability, simplicity, and adaptability. As the electronics industry continues to evolve, Flexible Test remains dedicated to overcoming these challenges, ensuring that PCB testing becomes a streamlined, cost-effective, and reliable process for manufacturers and developers alike.

Introducing Flexible Test: Your Partner in Excellence

Flexible Test stands at the forefront of revolutionizing PCB testing. With over two decades of experience, we understand the dynamic nature of electronics testing and the evolving needs of our clients. Our solutions go beyond the conventional, offering a range of benefits that can significantly enhance your PCB test fixture design.

Optimizing Connector Reliability

One of the critical aspects of PCB testing is the reliability of connectors. Traditional connectors, such as Zero Insertion Force (ZIF) connectors, can be prone to wear and tear, leading to frequent replacements and disruptions in testing routines. Flexible Test addresses this challenge by providing engineered contacts that are built to endure thousands of cycles. These contacts ensure long-lasting reliability, eliminating the hassle of broken latches and the need for constant replacements.

Streamlining Setup with Drop-In Solutions

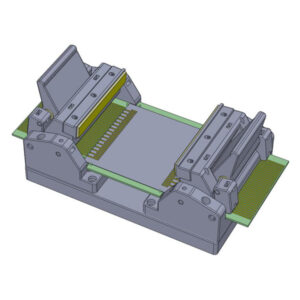

Efficiency is the key to a successful testing process. Flexible Test offers hassle-free drop-in solutions that bridge the gap between your Device Under Test (DUT) and test equipment. Our fixtures are designed for straightforward setup, eliminating the need for complex configurations or adjustments. This seamless integration enhances overall testing efficiency, ensuring that you can meet deadlines and deliver reliable results.

Reducing Maintenance Costs

Investing in durable engineering is a cost-effective approach, and Flexible Test understands the importance of minimizing long-term maintenance expenses. Our fixtures are constructed with robust engineering to withstand thousands of testing cycles. By reducing the need for frequent replacements and repairs, our solutions help you save on maintenance costs, contributing to the overall efficiency and sustainability of your testing processes.

Expert Support for Thorough Design

At Flexible Test, we recognize that each testing scenario is unique. Our expert support goes beyond providing off-the-shelf solutions. We analyze your needs and can work closely with your team, crafting efficient FFC test fixtures tailored to your specific requirements. We offer full 2D and 3D design support for all fixture models, ensuring that you receive a thorough design service that aligns with your testing goals.

Enhancing Workflow with Customization

Flexibility is at the core of our solutions. We understand that not all testing requirements are the same, and our highly customizable fixtures allow you to tailor our products to your specific needs. Whether you require specialized features or adjustments for a particular DUT, Flexible Test provides the flexibility to enhance your workflow and ensure that your testing process runs seamlessly.

Building a Strong Partnership

The foundation of Flexible Test’s success lies in building strong partnerships with our clients. We value the feedback and insights of our customers, using their experiences to continually improve and innovate our solutions. Our commitment to customer satisfaction is evident in every aspect of our service, from the reliability of our fixtures to the efficiency of our support.

Conclusion

In conclusion, Flexible Test stands as a beacon of excellence in the realm of PCB testing. Our solutions are designed not just to meet industry standards but to exceed them. By optimizing connector reliability, streamlining setup with drop-in solutions, reducing maintenance costs, providing expert support for thorough design, and enhancing workflow with customization, we offer a comprehensive approach to PCB test fixture design.

Elevate your PCB testing processes with Flexible Test and experience the difference that precision engineering, durability, and flexibility can make in ensuring the reliability and functionality of your electronic devices. As the electronics industry continues to advance, Flexible Test remains your trusted partner in optimizing PCB test fixture design for the challenges of tomorrow.