Our Fixtures

Flexible Test Features And Benefits

Typical Fixture Application

- Streamlining Electronic Testing

- Our Flexible Test FFC Test Fixtures are engineered to streamline electronic testing, making the process efficient and reliable for a wide array of applications.

- Reliability

- Boasting an impressive cycle count of 20,000+, our fixtures are built to last, ensuring consistent performance even in the most demanding conditions. They are also field replaceable, reducing downtime and maintenance hassles.

- Proven Track Record

- Trusted by hundreds of satisfied customers worldwide, our Flexible Test FFC Test Fixtures have been successfully integrated into thousands of installations, affirming their effectiveness and quality.

- Cost-Effective

- Offering cost-effective solutions without compromising on quality, our fixtures are a wise investment for businesses of all sizes.

- Expert Support

- We provide comprehensive technical support and expertise to ensure a seamless integration of our fixtures into your electronic testing processes.

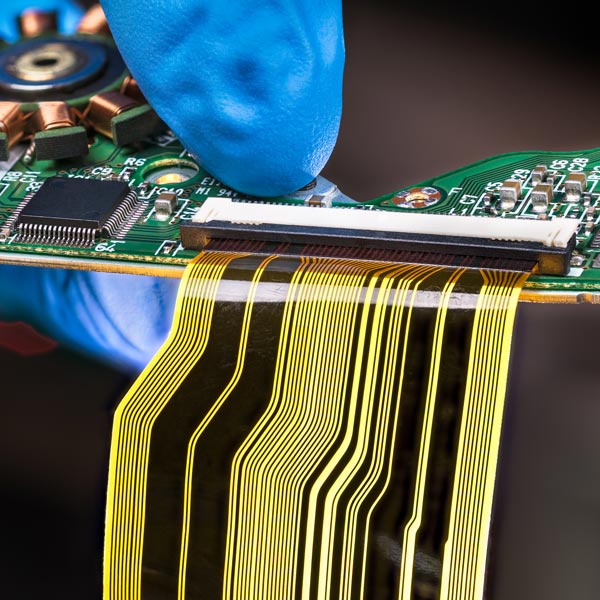

Flexible Circuits

Flexible circuits are used in many electronic devices to carry power and control signals to/from mating electronics. Flat Flex Cables (FFC) and Flat Printed Circuits (FPC) are widely used in virtually all industries as the most common way to economically connect many high-density interconnects in a low-profile small PCB footprint.

To learn more about flexible circuits and their applications, take a look at our blog posts.

Proven Reliability

Flexible Test elements have been in use for 25+ years as a connection method.

Manufactured specifically for test fixture operation, their design mimics a standard FFC/FPC connector, while also providing long mechanical life as well. If an element needs to be replaced a new element can be installed in minutes.

Testing Solutions

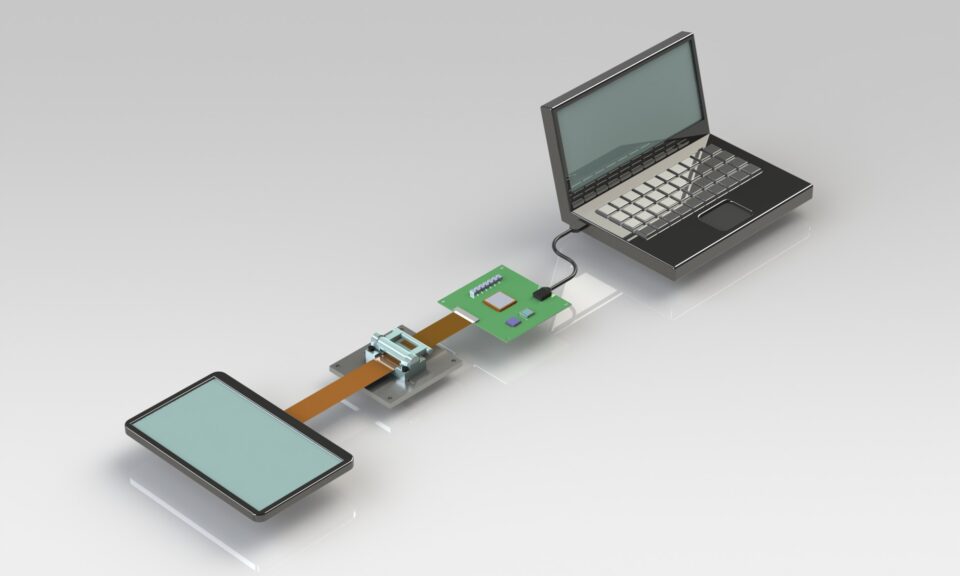

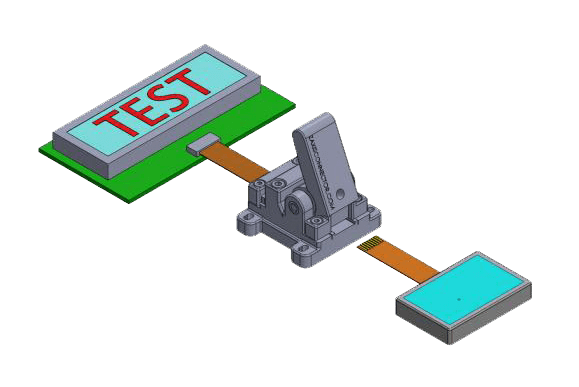

FlexibleTest fixtures are typically used between a DUT (device under test) and the electronics driving circuitry to operate or test the DUT. With an integrated FlexibleTest fixture, the connection is made once to the test board’s delicate ZIF or LIF connector.

This Test Repeats Thousands of Times

Fixture plugs directly into your test electronics

Your device-under-test easily inserts into your fixture

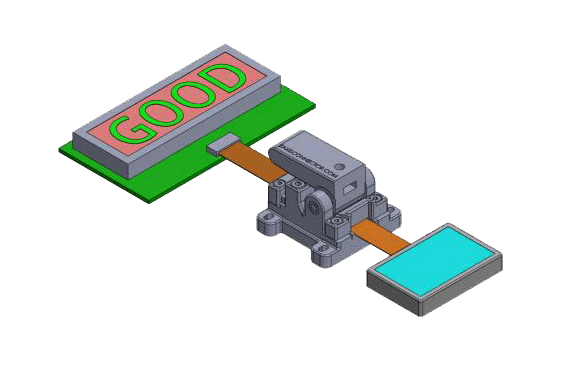

Your test sequence is executed as if the DUT is plugged directly into your ZIF or LIF

Test sequence executes reliably. No damage to your ZIF or LIF connector or DUT flex

Operator Simplicity

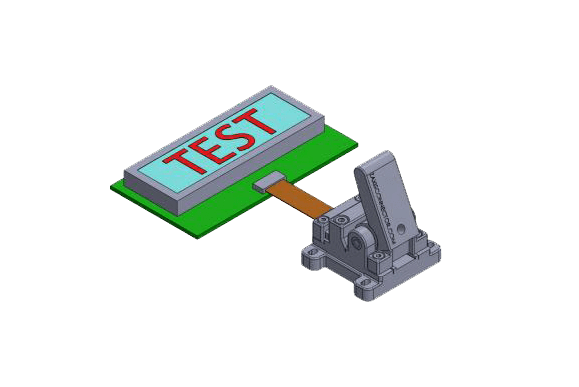

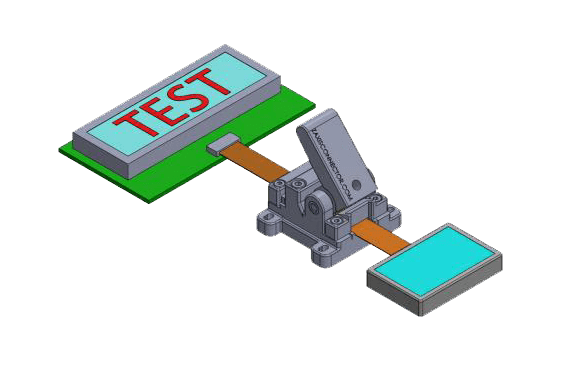

Moving the fixture’s ergonomic lever rotates a CAM which applies a compression force to a proprietary elastomeric element that bridges the DUT to the fixture’s termination FFC or PCB. The element compression is perpendicular to the circuit, which creates a soft contact that does not mark or indent the DUT flex. This further improves reliability when the DUT is later integrated into the final product. When the electrical test is complete the reverse motion of the lever CAM reduces the force, uncompressing the elastomeric element. This allows a zero force removal of the DUT flex.

Limitation With ZIF & LIF Connectors

Low-profile ZIF and LIF (zero and low insertion force) connectors are used to interface FFC – FPC circuits to PCBs. While ZIF and LIF connectors are great for meeting the product needs of integrated electronics the connectors have a limited actuation life creating a significant need to testing FFC – FPC based electronics. In addition, ZIF and LIF small formats are difficult to work with due to their small size, creating a secondary need for a fixture that is more ergonomic for operators and adaptable for automation.