Cost-Optimized FFC Interface for Production and Engineering

Flat Flex Cables (FFCs) are a critical interconnect technology in modern electronics, enabling high-density signal routing in extremely limited mechanical space. At the same time, their fine pitch and delicate structure make them one of the more difficult interconnects to validate reliably in a production environment.

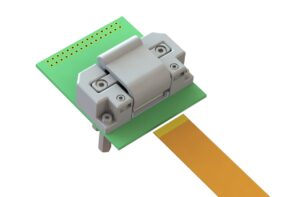

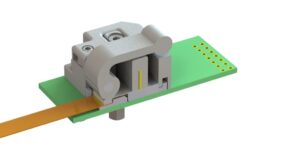

FlexibleTest has long specialized in purpose-built FFC test fixtures for these exact challenges. This new FFC Test Interface builds on that experience, delivering a smaller, lower-cost, and easier-to-integrate solution for applications where a full-size custom fixture is unnecessary, but repeatable electrical contact is still essential.

Market Need

In many manufacturing and engineering environments, test space is limited and budgets are tightly controlled. Traditional FFC fixtures can be overkill when:

-

The pin count is moderate

-

The test scope is focused on continuity or basic functional validation

-

Multiple test stations are required

-

The mechanical envelope inside the test system is constrained

This product was developed specifically to address these scenarios by providing a streamlined, production-grade interface without the cost and complexity of larger fixture systems.

Design Philosophy

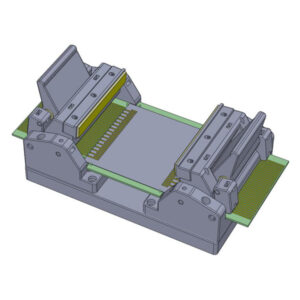

The fixture was engineered with three primary design drivers:

-

Compact Form Factor

A reduced footprint and low Z-height allow this unit to fit into tight test platforms, multi-up nests, and automated handling systems. -

Cost Optimization

The mechanical architecture is simplified while preserving critical alignment and contact control features, resulting in a lower overall fixture cost. -

Repeatability and Reliability

Controlled compression and guided insertion ensure stable contact performance across high-cycle use.

Mechanical Architecture

The unit utilizes a rigid base structure with a hinged actuation mechanism that applies even, predictable force across the FFC contact interface. Precision datum surfaces maintain cable alignment and parallelism during each test cycle, minimizing variability and reducing operator dependency.

The guided insertion path protects the cable from edge damage and skew, extending cable life during repeated test operations.

Electrical Interface Performance

Direct access to the FFC conductors is achieved through a dedicated contact interface optimized for fine-pitch geometries. Compared to traditional mating connectors, this approach offers:

-

Reduced wear mechanisms

-

Improved stability for high-density signal routing

-

Better long-term performance in production environments

Integration Flexibility

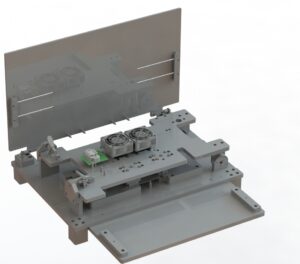

While compact, the fixture is designed as a modular building block:

-

Drops into existing bed-of-nails and functional test systems

-

Supports manual, semi-automated, and automated test cells

-

Easily scalable to multi-up configurations

-

Compatible with a wide range of FFC sizes and pitches

This makes it well suited for both engineering validation and volume manufacturing.

Production Benefits

From an operations standpoint, this interface provides:

-

Reduced capital cost per test station

-

Smaller mechanical envelope in the test cell

-

Faster operator training and interaction

-

Lower maintenance compared to standard FFC sockets

-

Improved test yield through more consistent contact performance

Typical Applications

-

FFC cable assembly verification

-

Continuity and insulation resistance testing

-

Programming and functional validation

-

End-of-line production screening

-

Engineering bring-up and characterization

Conclusion

This compact FFC Test Interface expands the FlexibleTest portfolio by offering a high-performance, economical alternative to traditional FFC fixtures. It delivers the contact reliability and mechanical stability FlexibleTest is known for, in a smaller and more accessible form factor.

For customers who need dependable FFC testing without the size and cost of a full custom fixture, this solution provides a practical and scalable path forward.