From Manual to Modern: FFC Testing Explained

Flat Flexible Cables (FFC) are essential in modern electronics, connecting PCBs, displays, sensors, and more. As devices become smaller and more complex, ensuring reliable FFC performance is critical. Testing these cables effectively can save time, reduce errors, and prevent costly production setbacks.

In this article, we’ll compare traditional FFC testing methods with modern fixture-based testing, highlighting the advantages of using flexible test fixtures in today’s production environments.

Traditional FFC Testing Methods

Historically, FFC testing relied on manual or semi-manual processes, which can include:

-

Multimeter Testing

-

Engineers manually check continuity and resistance between individual conductors.

-

Challenges: Slow, prone to human error, not feasible for high-volume production.

-

-

Bed-of-Nails Testers

-

Spring-loaded pins contact each FFC conductor simultaneously.

-

Challenges: Expensive to build for small or fine-pitch cables, requires precise alignment, and can damage delicate FFCs.

-

-

Hand-Soldered or Temporary Connections

-

In early-stage prototypes, engineers may solder wires or use clip adapters.

-

Challenges: High risk of mechanical stress, inconsistent contact, and time-intensive setup.

-

Drawbacks of Traditional Methods:

-

Time-consuming: Manual testing slows down production cycles.

-

Inconsistent results: Human error and mechanical wear can introduce variability.

-

High labor cost: Requires skilled technicians for reliable testing.

-

Limited scalability: Difficult to implement for high-volume manufacturing or automated lines.

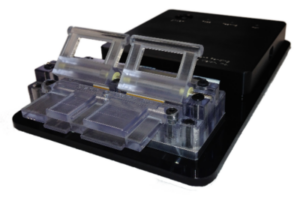

Modern Fixture-Based FFC Testing

Modern testing solutions use dedicated fixtures designed for specific FFC types and applications. These fixtures are engineered to provide consistent contact, repeatable results, and compatibility with automated systems.

Key Features:

-

Precision Alignment

-

Fixtures hold the FFC in an exact position, ensuring reliable contact with each conductor.

-

-

Pass-Through Capabilities

-

Some fixtures allow the device under test to remain connected for programming or functional testing while performing continuity checks.

-

-

Automation-Friendly

-

Fixtures can integrate with PLCs, test software, and production lines to allow automated testing of hundreds of cables per hour.

-

-

Durability & Repeatability

-

Engineered contacts reduce wear on FFCs, minimize damage, and deliver consistent measurements across batches.

-

Advantages over Traditional Methods:

| Feature | Traditional Testing | Fixture-Based Testing |

|---|---|---|

| Speed | Slow | Fast and automated |

| Accuracy | Human-dependent | High precision and repeatable |

| Labor | Skilled technicians required | Can be automated or operated by less-trained staff |

| Scalability | Poor | Excellent for high-volume production |

| FFC Longevity | Potentially damaging | Gentle and designed for repeated use |

Why Fixture-Based Testing Matters

In modern electronics manufacturing, speed and accuracy are critical. Small misalignments or faulty connections can cause product failures and expensive recalls. Fixture-based FFC testing:

-

Reduces human error and variability

-

Speeds up production testing cycles

-

Protects delicate cables from mechanical stress

-

Enables integration with automated test stations for functional testing

In short, it allows manufacturers to scale quality assurance without compromising reliability.

Conclusion

While traditional FFC testing methods served their purpose in early electronics manufacturing, they are increasingly insufficient for today’s high-speed, high-precision production environments. Modern fixture-based testing offers a faster, safer, and more reliable approach to FFC verification.

At Flexible Test, our fixtures are engineered to provide precision alignment, repeatable results, and automation compatibility, making FFC testing efficient and reliable, whether you’re handling a small batch or high-volume production.

Interested in upgrading your FFC testing process? Contact us today to learn how our flexible test fixtures can streamline your production workflow.