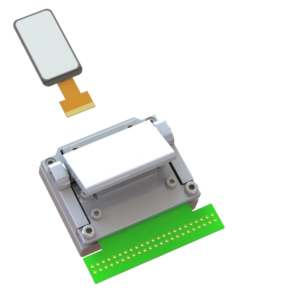

Introducing Our 0.3mm FFC Test Fixture

Testing micro-pitch connectors requires absolute precision to ensure every connection works. Even the smallest misalignment can lead to unreliable connections, device failures, or costly rework. That’s why we designed our new 0.3 mm test fixture, engineered to deliver unmatched precision and reliability for your most demanding applications.

Why Micro-Pitch Demands Specialized Fixtures

Micro-pitch FFCs and PCB connectors present unique challenges. Traditional fixtures may struggle with alignment, contact consistency, and long-term durability, particularly in dual-row or high-density designs. Our 0.3 mm fixture addresses these issues head-on:

-

Dual-Row Capability: Designed to reliably interface with tightly spaced rows of pads, ensuring every contact is accurate.

-

High Precision Alignment: Built to micron-level tolerances, reducing the risk of failed connections or false readings.

-

Durable Construction: Engineered for repeated use in production and testing environments without compromising performance.

From Concept to Testing

Unlike standard fixtures, our 0.3 mm design integrates advanced mechanical and electrical engineering to provide a seamless interface for both FFC and PCB-based terminations. Whether you’re prototyping a new device or performing high-volume testing, this fixture simplifies setup while ensuring reliable, repeatable results.

Applications That Benefit

Our new fixture is perfect for:

-

High-density PCBs where micro-pitch connectors are required.

-

Automated test setups that demand repeatable precision.

-

Production environments that need durability and accuracy over hundreds or thousands of cycles.

Ready to Elevate Your Testing Process?

With our 0.3 mm micro-pitch test fixture, you get precision, reliability, and efficiency—all in a compact, robust design. Don’t compromise your testing standards: ensure every connection counts.

Learn more about our 0.3 mm test fixture and how it can improve your testing workflow.