Revolutionizing Electronics Testing with Custom Functional Test Fixtures by Flexible Test

In today’s rapidly evolving electronics industry, ensuring the functionality and reliability of electronic devices is paramount. Custom Functional Test Fixtures are at the forefront of this challenge, providing tailored solutions for a diverse range of electronic products. Leading the charge in this field is Flexible Test, a prominent manufacturer known for their intuitive and adaptable test fixtures. In this article, we will explore the world of custom functional test fixtures, the role they play in the electronics manufacturing process, and how Flexible Test’s products are transforming the industry.

The Significance of Custom Functional Test Fixtures

Custom Functional Test Fixtures are specialized tools that serve as a bridge between the design and production phases of electronic devices. They play a crucial role in the quality control and verification process. These fixtures are custom-designed to address the unique needs of individual electronic products, ensuring that they perform as intended. The benefits of custom functional test fixtures are extensive and include:

- Precision Testing: Custom fixtures are tailored to the specific device’s design, allowing for highly precise testing, which is essential for intricate electronic components.

- Efficiency: With tailored fixtures, the testing process becomes highly efficient, reducing the time and resources required for quality assurance.

- Cost Savings: Custom fixtures eliminate the need for redundant testing equipment, leading to significant cost savings in the long run.

- Consistency: Custom fixtures ensure that each product undergoes the same rigorous testing, maintaining consistency in product quality.

- Flexibility: These fixtures can adapt to various products and can be easily reconfigured for new devices, reducing downtime.

Flexible Test: Pioneers in Custom Functional Test Fixtures

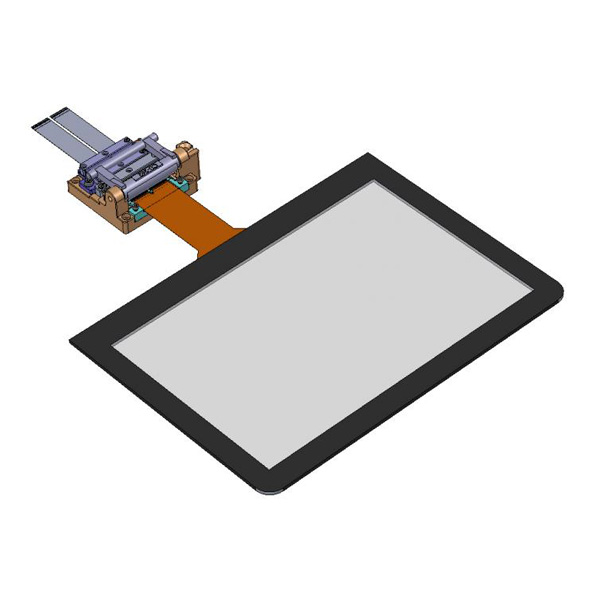

Flexible Test is a renowned manufacturer at the forefront of custom functional test fixtures for Flexible Flat Cable (FFC) and Flexible Printed Circuit (FPC) devices. Their intuitive products are making waves in the electronics manufacturing industry, offering a level of adaptability and efficiency that is redefining the testing process.

Key Features of Flexible Test’s Custom Functional Test Fixtures

- Customization Beyond Compare:

- Flexible Test’s fixtures are designed to be truly customizable, catering to the specific requirements of each electronic product.

- This level of customization ensures that every test is tailored to the device’s unique features, improving accuracy and reliability.

- Diverse Product Compatibility:

- The range of products that Flexible Test’s fixtures can handle is extensive, covering a wide spectrum of FFC and FPC devices.

- Manufacturers can rely on a single fixture for a multitude of testing needs, reducing the need for multiple specialized fixtures.

- Rapid Setup and Configuration:

- Time is of the essence in the fast-paced world of electronics manufacturing. Flexible Test’s fixtures can be set up in a matter of minutes, reducing downtime and enhancing production efficiency.

- This rapid setup ensures that manufacturers can quickly adapt to changes in production requirements without significant delays.

The Versatility of Custom Functional Test Fixtures

Custom functional test fixtures offer versatility that extends far beyond traditional, one-size-fits-all testing equipment. Their adaptability allows manufacturers to address the unique challenges presented by various electronic products. Here’s a closer look at the versatility that custom fixtures provide:

1. Complex FFC and FPC Devices:

- Many modern electronic devices rely on intricate Flexible Flat Cables (FFC) and Flexible Printed Circuits (FPC) to function. Custom fixtures are adept at testing these complex devices with precision.

2. Multiple Testing Needs:

- Electronic products come in various shapes and sizes, with differing testing requirements. Custom fixtures can accommodate a broad range of testing needs, from simple connectors to more complex electronic components.

3. Rapid Prototyping:

- In the ever-changing electronics landscape, the ability to quickly prototype and test new products is invaluable. Custom functional test fixtures offer a means to adapt testing processes as new devices are developed.

4. Scalability:

- As production volumes change, custom fixtures can be easily scaled to meet increased demand. This scalability ensures that the testing process remains efficient even as production levels fluctuate.

Case Studies: Real-World Benefits of Custom Functional Test Fixtures

Let’s delve into a few real-world scenarios where Flexible Test’s custom functional test fixtures have made a significant impact:

1. Enhanced Product Quality:

- A manufacturer of advanced medical devices required rigorous testing to ensure product reliability. Flexible Test’s custom fixture allowed for precise testing of the devices, reducing defects and improving overall product quality.

2. Time and Cost Savings:

- An electronics company dealing with a diverse product line needed a way to streamline their testing process. The custom fixture by Flexible Test significantly reduced setup times, saving both time and money.

3. Quick Adaptation to New Products:

- A tech company frequently launched new electronic products. With Flexible Test’s custom fixtures, they could adapt their testing processes rapidly to accommodate each new device’s unique features.

4. Efficient Scalability:

- A manufacturer of consumer electronics experienced fluctuating production demands. The custom fixtures allowed them to easily scale their testing procedures, optimizing efficiency during peak periods and reducing costs during lulls.

The Future of Electronics Testing

Custom functional test fixtures are revolutionizing the electronics industry, and Flexible Test is leading the charge with their intuitive and adaptable solutions. As the demand for smaller, more intricate electronic devices continues to grow, the need for precise, efficient, and adaptable testing methods becomes increasingly important.

Manufacturers are facing an ever-increasing demand for more sophisticated and compact electronic devices, and in this landscape, the one-size-fits-all approach to testing is no longer sufficient. The rapid pace of innovation in the electronics industry demands flexibility, precision, and efficiency in the testing process. In embracing the customization and adaptability these fixtures provide, manufacturers are not just meeting industry standards; they are setting new benchmarks for excellence in electronics testing. Flexible Test’s unwavering dedication to innovation and their capacity to deliver tailor-made testing solutions position them as a pivotal force in this swiftly evolving field, driving the electronics industry forward and ensuring that every device that reaches the hands of consumers is built on a foundation of quality and reliability.

Conclusion

In conclusion, the role of custom functional test fixtures in the electronics manufacturing process cannot be overstated. These fixtures are the linchpin between product design and market readiness. Flexible Test’s products, with their unparalleled customizability, product compatibility, and rapid setup capabilities, are poised to play a pivotal role in shaping the future of electronics testing, ensuring that the devices we rely on are of the highest quality and reliability.