Stronger Fixtures for Demanding Test Environments

Test fixtures used in production experience repeated cycles, operator handling, side loading, and occasional impacts. Over time, these forces reveal weaknesses in materials and geometries that may be acceptable for prototypes but are not suitable for long term production use.

At FlexibleTest, we have upgraded both the material and the mechanical design of key fixture components to deliver substantially higher strength and durability.

Why Fixture Material and Geometry Matter

Many fixtures rely on clear prototype materials that are easy to manufacture but relatively brittle. Common failure modes include cracking near fasteners, flexing of levers, and fracture after extended use. These issues lead to downtime, replacement costs, and inconsistent test results.

For components that experience bending loads, such as levers, pins, and cylindrical features, strength is strongly influenced by the section modulus of the part.

Bending Strength and Section Modulus

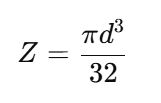

For a solid circular cross section, the section modulus in bending is given by:

This relationship shows that bending strength scales with the cube of the diameter. Even modest increases in diameter result in significant gains in stiffness and strength.

Quantifying the Design Improvement

In the previous design, cylindrical features used a diameter of 4.76 mm and were manufactured from a clear prototype material. In the updated design, the diameter was increased to 6.5 mm and paired with a much stronger engineering material.

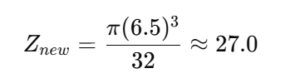

Using the section modulus equation:

Old Design:

New Design:

From geometry alone, the section modulus increases by approximately 2.5 times. When combined with the higher strength material compared to the original clear material, the effective bending strength improvement exceeds 150 percent in real world use.

Where the Stronger Design Is Applied

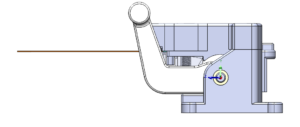

The upgraded material and geometry are applied specifically to high stress fixture components, including:

Actuation levers and rotating features

Fixture bodies and structural components

Alignment and retention features

Operator interface components

This targeted approach improves durability without unnecessary cost increases.

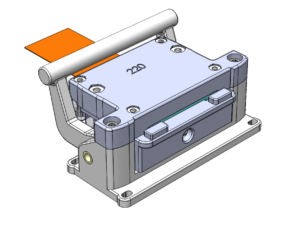

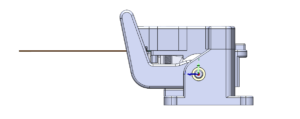

Old Design:

New Design and Material:

Built for High Cycle Production Use

FlexibleTest fixtures are commonly used in high cycle production testing, incoming inspection, programming, and functional verification. The increased stiffness and strength help maintain alignment and repeatability over thousands of cycles while reducing the likelihood of cracked or failed components.

Better Durability and Long Term Value

By combining stronger materials with improved mechanical design, our fixtures last longer and perform more consistently in production environments. This results in fewer failures, reduced downtime, and a lower total cost of ownership.

If your current fixtures are showing signs of wear or mechanical failure, we can help identify where material and geometry improvements can make the biggest impact.