The Power of Automated Test Fixtures by Flexible Test

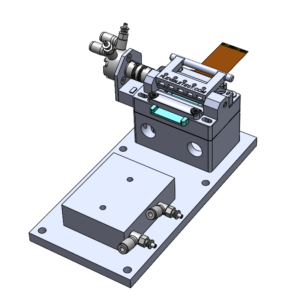

Pneumatically Automated Test Fixture Built by Flexible Test

The demand for efficient and precise electronic testing solutions has never been higher. At Flexible Test, we stand at the forefront of this evolution, bringing over two decades of experience and expertise in the development of Automated Test Fixtures. Our commitment to innovation and excellence has led us to collaborate with top-tier companies, tailoring solutions that redefine the standards of automated testing.

Collaborating with Industry Leaders:

At Flexible Test, we pride ourselves on collaborating with industry leaders to develop bespoke Automated Test Fixtures that cater to specific project requirements. Our proven track record showcases our ability to understand the unique needs of diverse applications, ensuring that our fixtures deliver unparalleled performance and reliability.

Whether it’s partnering with leading automotive manufacturers for testing intricate vehicle electronics or teaming up with cutting-edge medical device companies to ensure the reliability of life-saving equipment, our collaborative approach has consistently resulted in state-of-the-art Automated Test Fixtures. By engaging in close consultations with our clients, we gain insights into the intricacies of their testing requirements, enabling us to engineer fixtures that not only meet but exceed expectations.

This collaborative spirit is embedded in our DNA, and it reflects our commitment to pushing the boundaries of what’s possible in automated testing. The success stories of these partnerships underscore our ability to address the unique challenges of diverse industries, reinforcing our position as a trusted partner in the pursuit of testing excellence.

Electrically and Pneumatically Controlled Solutions:

Our Automated Test Fixtures go beyond the conventional, offering both electrically and pneumatically controlled fixtures. Whether you’re seeking a drop-in solution for automation-ready testing or a system that seamlessly integrates into your existing setup, our fixtures provide the flexibility and adaptability needed in today’s dynamic manufacturing environment.

Electrically controlled fixtures offer precise and programmable control, allowing for intricate testing scenarios and ensuring consistent results. These fixtures are designed to seamlessly integrate into automated production lines, enhancing the overall efficiency of the manufacturing process.

On the other hand, our pneumatically controlled fixtures bring a different level of versatility to the table. With the ability to exert controlled pneumatic pressure, these fixtures are ideal for applications where specific force requirements are critical. This dual offering allows our clients to choose the solution that best aligns with their unique testing needs, ensuring a tailored approach that optimizes both precision and productivity.

Turn-Key Test Systems with User-Friendly Software:

As part of our commitment to providing end-to-end testing solutions, we have developed full turn-key test systems featuring user-friendly software. Our intuitive software interface simplifies the testing process, making it accessible even to non-experts. This ensures that your testing workflow remains efficient, reducing setup complexities and saving valuable time.

The heart of our turn-key systems lies in the sophistication of the software that drives them. We understand that a powerful Automated Test Fixture is only as effective as the software controlling it. Therefore, we’ve invested in developing user-friendly interfaces that empower operators with control and visibility over the entire testing process.

Navigating through our software is a seamless experience, allowing users to define test parameters, monitor real-time results, and generate comprehensive reports. This not only streamlines the testing workflow but also contributes to a more informed decision-making process. Our turn-key systems are engineered to enhance operational efficiency, offering a complete package that combines cutting-edge hardware with intuitive software, resulting in a harmonious synergy that elevates your testing capabilities.

Use-Case: Tailored Automation for PCAP Display Testing

One exemplary use-case that showcases the prowess of Flexible Test’s custom automated fixtures lies in the realm of PCAP (Projected Capacitive) display testing. Recognizing the critical role that PCAP displays play in modern electronic devices, we collaborated with a leading manufacturer to develop a bespoke Automated Test Fixture specifically designed for PCAP display testing.

Challenges in PCAP Display Testing:

PCAP displays, known for their widespread use in smartphones, tablets, and various touch-sensitive interfaces, come with unique testing challenges. Traditional testing methods often fall short when it comes to assessing the intricacies of PCAP displays, which require precise and reliable testing to ensure optimal performance.

Our Custom Automated Fixture Solution:

Understanding the intricacies of PCAP display testing, we embarked on a collaborative journey with our client to engineer a custom automated fixture tailored to their specific requirements. The fixture was designed to address the challenges posed by PCAP displays, offering a solution that goes beyond the capabilities of off-the-shelf fixtures.

Key Features of the Custom Fixture:

1. Precision in Touchpoint Detection:

- Our custom automated fixture ensures precision in touchpoint detection, addressing the specific needs of PCAP displays. With the ability to send controlled signals and accurately measure the responses, the fixture enables thorough testing of touchpoints, ensuring the reliability of the display’s interactive features.

2. Comprehensive Diagnostics:

- The fixture incorporates advanced diagnostics, allowing for a comprehensive analysis of the PCAP display’s performance. From detecting and identifying individual touchpoints to assessing multi-touch functionalities, our custom solution provides a detailed and insightful diagnostic report.

3. Efficient Testing Workflow:

- Designed for seamless integration into the client’s existing testing setup, the custom automated fixture streamlines the testing workflow. Automation features enable efficient and repeatable testing, reducing the time required for testing cycles and enhancing overall productivity.

Results and Impact:

The deployment of our custom automated fixture for PCAP display testing resulted in a significant improvement in the efficiency and accuracy of the testing process. By addressing the unique challenges posed by PCAP displays, our solution empowered the client to deliver products with enhanced reliability and performance.

This use-case exemplifies the versatility and adaptability of Flexible Test’s Automated Test Fixtures. Whether you are dealing with PCAP displays or any other specialized testing requirements, our ability to tailor fixtures to your unique needs ensures that you receive a solution that not only meets but exceeds your expectations. Partner with Flexible Test to unlock the full potential of automated testing in your specific application.

Conclusion:

In conclusion, our Automated Test Fixtures represent a paradigm shift in the way testing is approached. Whether you are a major industry player or a startup with unique testing needs, Flexible Test is your trusted partner in achieving unparalleled testing efficiency. Explore the future of automated testing with Flexible Test and elevate your manufacturing processes to new heights.