What Is an FPC Test Connector and How Do They Work?

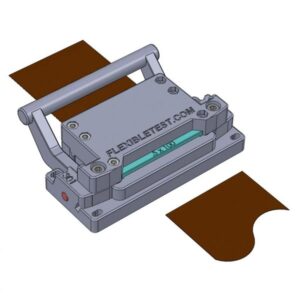

Flexible Test FPC Test Connector, Contact Pads Facing Down

Flexible printed circuits (FPC) are integral components in today’s electronic devices. From smartphones and laptops to medical equipment and automotive systems, FPCs are the unsung heroes that enable the flow of data and power. To ensure the reliability of these FPCs, testing is crucial, and FPC test connectors play a pivotal role in this process. In this article, we will delve into what FPC test connectors are and how they work, shedding light on their significance in ensuring the functionality of flexible printed circuits.

Understanding Flexible Printed Circuits (FPCs)

Before we dive into FPC test connectors, it’s essential to grasp the importance of flexible printed circuits in modern electronics. FPCs are thin, lightweight, and flexible substrates that provide an efficient means of connecting various electronic components within a device. They are often used in situations where traditional rigid PCBs would be impractical due to size, shape, or flexibility requirements.

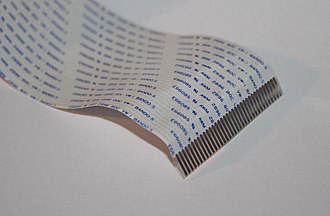

A Typical Cable

FPCs consist of a thin, flexible insulating base material (typically polyimide or polyester) with conductive traces that serve as the pathways for electrical signals. These circuits are found in numerous applications, including displays, touchscreens, cameras, and more.

The Role of FPC Test Connectors

FPCs, like any other electronic component, need to be thoroughly tested before they are integrated into a final product. This testing ensures that the FPCs function as intended and meet the required quality and reliability standards. FPC test connectors are specialized devices designed for this very purpose.

In contrast to conventional FPC connectors, such as ZIF-style connectors, which are not ideally suited for testing purposes due to their fragility and susceptibility to breakage, FlexibleTest emerges as a dependable solution. The role of FlexibleTest is to streamline and enhance the efficiency of your FPC test connector needs, saving both time and effort in the process.

What Are FPC Test Connectors?

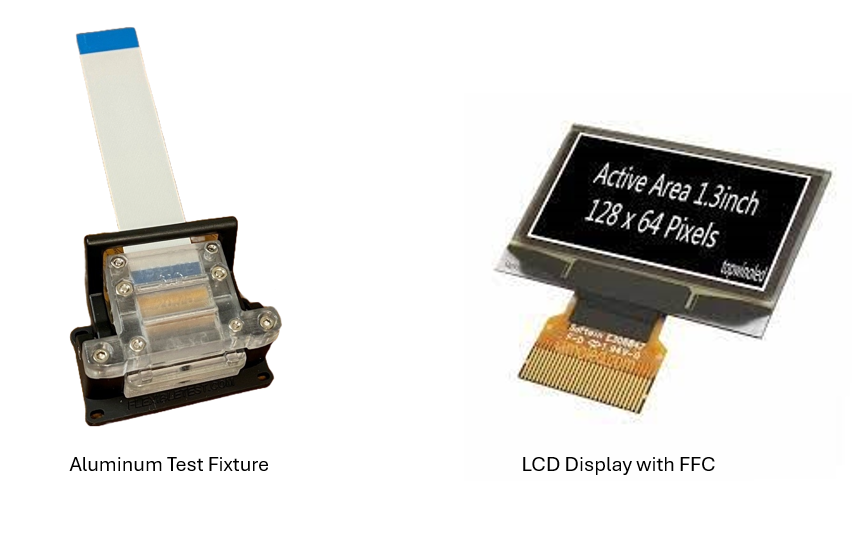

Standard Flexible Test Application

FPC test connectors serve as specialized interfaces, enabling seamless connections between FPCs and testing or inspection systems. Engineered for the secure and temporary connection of FPCs, they facilitate the transmission of electrical signals, data, and power, ensuring precise testing processes. These connectors are meticulously designed to guarantee a dependable and consistent connection, a pivotal factor in both quality control and manufacturing operations.

FlexibleTest stands out as a premier manufacturer of FPC Test Connectors, catering to a wide array of FPC devices. Our test connectors incorporate an innovative patented elastomeric connector and a user-friendly ergonomic lever, simplifying the process of FPC testing while ensuring efficiency and reliability.

How Do FPC Test Connectors Work?

FPC test connectors work by providing a secure interface between the FPC and the testing equipment. Here’s a step-by-step overview of how they operate:

- Alignment: The FPC is carefully aligned with the FPC test connector. Proper alignment is critical to ensure that the conductive traces on the FPC match up with the connector’s contact points.

- Clamping: Once aligned, the FPC is clamped in place, creating a stable connection. FlexibleTest uses elastomeric connectors that provide a soft actuation onto DUT pads.

- Electrical Connection: With the FPC securely in place, the FPC test connector establishes an electrical connection. This connection allows testing equipment to send and receive signals through the FPC, testing its functionality and integrity.

- Testing and Inspection: The testing equipment can now perform a variety of tests and inspections on the FPC. These tests may include checks for continuity, insulation resistance, impedance, and more. Any defects or irregularities in the FPC can be identified during this process.

- Data Collection: The results of the tests are collected and analyzed. This data is used to determine whether the FPC meets the required quality and performance standards.

- Release and Removal: Once testing is complete, the FPC test connector is released, and the FPC can be removed without damage or strain.

Why Choose FlexibleTest for Your FPC Test Connector Needs:

- Durability: Our FPC test connectors are engineered to withstand the test of time. With a remarkable rating of 20,000 cycles, they can handle repeated testing without breaking a sweat. Say goodbye to constant replacements and disruptions in your testing routine.

- Field Replaceable: When the inevitable does happen, and a connector needs replacement, we’ve got you covered. Our FPC test connectors are designed to be field-replaceable, minimizing downtime and ensuring your testing process remains efficient and uninterrupted.

- Reliability: At FlexibleTest, we understand the critical nature of device testing. Our FPC test connectors are crafted with precision and care, ensuring they consistently deliver reliable results, test after test.

- Customization: We understand that not all testing requirements are the same. That’s why we offer customization options, so you can tailor our fixtures to your unique needs.

- Expert Support: Our team of experts is ready to assist you every step of the way. From selecting the right fixture to providing technical support, we’re here to ensure your testing process runs seamlessly.

New Aluminum Test Fixtures

Conclusion

The continuous evolution of electronics and the growing demand for smaller, more flexible devices underscore the enduring importance of FPC test connectors. As technology advances and devices become more intricate, the reliability and precision of FPCs become even more crucial. FlexibleTest remains at the forefront of innovation, dedicated to delivering state-of-the-art FPC test connectors that keep pace with these dynamic changes. By ensuring that FPCs consistently meet stringent performance standards, they enable the development of cutting-edge electronics, from foldable smartphones to wearable health tech, offering a brighter and more connected future for us all.

FlexibleTest’s FPC test connectors are highly versatile, available in a diverse range of configurations tailored to accommodate the specific needs of various types of flexible printed circuits and diverse testing requirements. This adaptability makes them a valuable asset across a spectrum of industries, from manufacturing and quality control to research and development. Their role is paramount in guaranteeing the dependability and alignment of FPCs with the rigorous specifications demanded by their intended applications, whether in consumer electronics, medical devices, or automotive systems.

In summary, FPC test connectors play a pivotal role in the meticulous testing and quality assurance of flexible printed circuits. By establishing a secure and seamless connection between FPCs and testing equipment, these connectors ensure that these foundational elements of modern electronics meet the stringent standards for both functionality and reliability.