A Comprehensive Guide of Test Equipment Connectors from Flexible Test

In the dynamic world of electronic testing, where precision and efficiency are paramount, the choice of test equipment connectors plays a pivotal role. With traditional connectors often presenting a host of challenges, it’s time to explore the innovative realm of Flexible Test Connectors. In this comprehensive guide, we’ll delve into the myriad advantages these connectors offer over traditional counterparts, paving the way for a brighter and more efficient future in electronic testing.

Advantage 1: User-Friendly Design

The hallmark of Flexible Test Connectors lies in their user-friendly design. With an ergonomic CAM lever, connecting and disconnecting these connectors becomes a breeze. No more struggling with cumbersome setups or fiddly components. This user-friendly feature not only simplifies the testing process but also boosts the overall efficiency of your team, allowing them to concentrate on what truly matters – the testing itself.

Our test connectors can be set up in a matter of minutes, eliminating the need for time-consuming and intricate configurations. This streamlined process empowers your team to initiate testing swiftly, saving precious time and resources. As an additional advantage, you can repeat your testing procedure thousands of times before any maintenance is required. This reliability ensures that your testing workflow remains uninterrupted and your team can stay focused on the critical task at hand – accurate and meticulous testing.

Traditional connectors, with their intricate setups and fiddly components, can often lead to unnecessary delays and frustrations. In contrast, Flexible Test Connectors prioritize simplicity and efficiency, ensuring that your testing team can perform at their best, even under demanding schedules. With setup times reduced to mere minutes and maintenance requirements spaced out over an extended period, you gain the flexibility to allocate your resources where they matter most – optimizing your testing processes and achieving superior results

Advantage 2: Time-Saving Solution

Time is money, especially in the fast-paced world of electronics. Traditional connectors often demand a significant amount of time for setup and troubleshooting, eating into your precious testing window. Flexible Test Connectors, on the other hand, are a time-saving solution par excellence. They seamlessly integrate into your testing setup, eliminating complex configurations and reducing the time spent on troubleshooting. This efficiency allows your team to focus on what they do best – precise and accurate testing.

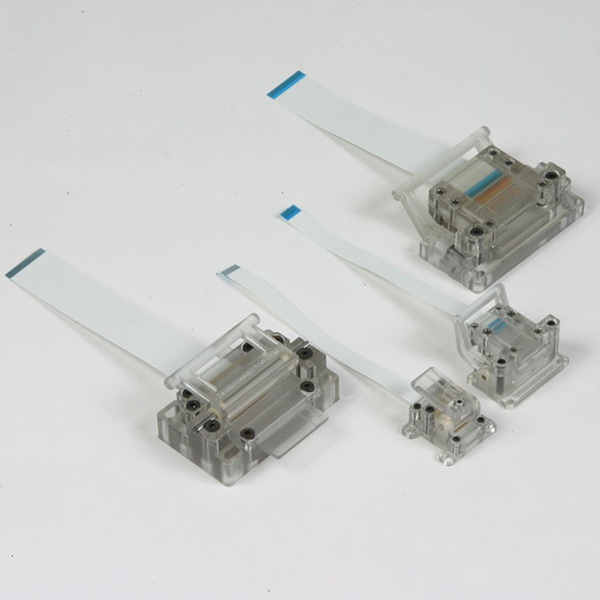

We typically offer our test connectors with either an FFC or PCB output, giving you the flexibility to choose the output that aligns perfectly with your specific testing requirements. Whether you prefer to set up the test connector directly with your existing testing equipment or opt to solder discrete wires directly to the fixture, our connectors adapt to your preferred approach. This versatility streamlines the setup process, further reducing the time required for configuration and ensuring a seamless integration into your existing testing environment.

With Flexible Test Connectors, the agility to select the output option that suits your needs not only enhances the efficiency of your setup but also underscores the adaptability of these connectors. Whether you’re working with a well-established testing environment or need a tailored solution to match the unique aspects of your testing procedures, our connectors empower you with the choice to optimize your setup process according to your preferences. This adaptability is a reflection of our commitment to ensuring your testing experience is both efficient and tailored to your specific needs.

Advantage 3: Versatile Applications

One of the standout features of Flexible Test Connectors is their adaptability. They are not confined to a single industry or specific application. Whether you’re in the consumer electronics sector, aerospace, automotive, or any other field, these connectors effortlessly accommodate a broad spectrum of testing scenarios. This versatility is a game-changer, as it provides flexibility and future-proofing for your testing needs.

A recent success story at Flexible Test exemplifies the incredible adaptability of our connectors. A leading medical device company faced a unique challenge – they required a test connector for their FPC with a remarkably compact working area, measuring just 4.5mm. Recognizing the flexibility and expertise of Flexible Test, they reached out for a solution to meet their specific needs.

Our team rose to the occasion, swiftly designing and delivering a customized test connector that not only met their tight deadline but exceeded their expectations. The medical device company was so impressed with the time-saving solution that Flexible Test had provided that they decided to order more test connectors to outfit their entire setup. This real-world success story underscores how Flexible Test Connectors empower businesses to overcome complex challenges and optimize their testing processes, regardless of the industry or application

Advantage 4: Exceptional Durability with a 20,000+ Cycle Rating

Flexible Test Connectors are engineered to last. Their robust design ensures they can withstand a staggering 20,000+ mate/demate cycles. This remarkable cycle rating reflects their longevity and resilience, making them a sound investment for businesses seeking long-term, reliable testing solutions. Say goodbye to the constant hassle of connector replacements and repairs – these connectors are built to endure.

Advantage 5: Comprehensive Design Support

At Flexible Test, we understand that no two testing scenarios are alike. That’s why our Flexible Test Connectors come with comprehensive design support. Our team works closely with you to tailor solutions that precisely fit your unique requirements. From initial design to implementation, we are here to ensure a seamless integration of these connectors into your testing processes.

But our commitment to your success doesn’t end with the delivery of your Flexible Test Connectors. We understand that ongoing support is crucial to ensure that your testing processes continue to operate at their best. That’s why we go the extra mile to work closely with your team even after your test connectors are installed.

Our dedicated support doesn’t stop at the point of installation. We remain by your side, ready to address any questions or concerns that may arise. Our team is fully committed to ensuring that everything functions as intended. Whether it’s fine-tuning your testing setup, troubleshooting any unexpected issues, or simply providing expert advice, you can rely on our ongoing assistance to keep your testing processes running smoothly.

Advantage 6: Proven Expertise

With over 25 years of experience in custom device testing, Flexible Test is a name you can trust. Our extensive experience means that our connectors are not just innovative but also thoroughly tested and reliable. Our deep insights into various industries and applications make us your go-to partner for crafting efficient FFC test fixtures that go beyond industry standards.

Conclusion

The advantages of Test Equipment Connectors from Flexible Test over traditional counterparts are clear and compelling. Their user-friendly design, time-saving capabilities, versatility, exceptional durability, comprehensive design support, and proven expertise make them a must-have solution for electronic testing. By making the switch to Flexible Test Connectors, you’re not just embracing innovation; you’re ensuring efficiency, reliability, and accuracy in your testing processes. It’s time to unlock the future of test equipment connectors with Flexible Test.