Upgrade Your PCB Test Fixture with Flexible Test

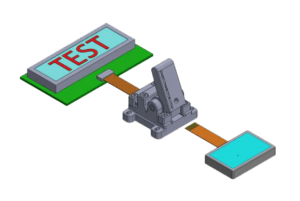

In the fast-paced world of electronics, reliable PCB (Printed Circuit Board) testing is paramount. Ensuring the quality and functionality of your PCBs is not only essential for your products but also for your reputation in the market. However, traditional testing methods often come with their share of challenges, such as the use of ZIF connectors and pogo pins, which are notorious for being unreliable and prone to failure. Fortunately, there’s a solution that offers simplicity, durability, and superior performance: Flexible Test Fixtures.

Flexible Test Fixtures: A Game-Changer for PCB Testing

Flexible Test Fixtures, a drop-in solution for your PCB testing needs, have been making waves in the industry for several compelling reasons. These fixtures offer a set of features and benefits that address many common pain points associated with traditional PCB test fixture designs:

1. Simplicity and Ease of Use: One of the most significant advantages of Flexible Test Fixtures is their simplicity and ease of use. They are designed to seamlessly integrate into your existing testing processes, making the transition smooth and hassle-free. With no complex setups or configurations required, your team can be up and running in no time.

2. Remarkable Durability: Flexible Test Fixtures are engineered for the long haul. Rated at an astonishing 20,000+ cycles, these fixtures are built to withstand the rigors of frequent testing without breaking a sweat. Their field-replaceable nature means that maintenance is a breeze, reducing downtime and ensuring continuous operation.

3. Say Goodbye to ZIF Connectors and Pogo Pins: Many PCB testing fixtures rely on ZIF (Zero Insertion Force) connectors and pogo pins. However, these components are known for their unreliability and susceptibility to failure over time. Flexible Test Fixtures eliminate the need for such delicate components, significantly reducing the risk of testing errors and costly replacements.

4. Preserving PCB Integrity: Traditional testing methods often leave unsightly wear marks on your PCBs, affecting their aesthetics and potentially compromising their functionality. Flexible Test Fixtures, on the other hand, leave no marks behind, ensuring that your PCBs maintain their pristine condition.

5. Versatility: These fixtures are adaptable to a wide range of applications and industries, from consumer electronics and automotive to aerospace and telecommunications. No matter your testing requirements, Flexible Test Fixtures can cater to your needs.

6. Cost-Effective Solution: By providing a drop-in solution that eliminates the need for costly ZIF connectors and pogo pins, Flexible Test Fixtures offer a cost-effective way to enhance your testing processes without sacrificing quality.

The Mechanics Behind Flexible Test Fixtures

At the heart of the innovation offered by Flexible Test Fixtures lies a meticulously engineered system that simplifies PCB testing while providing a level of reliability and versatility that is unparalleled in the industry. In this section, we will delve into the inner workings of these fixtures, explaining how they function and why they are a game-changer for PCB testing.

Gentle and Precise Actuation

The secret behind the success of Flexible Test Fixtures is the use of elastomeric connectors. These connectors are designed to gently actuate onto device contact pads, ensuring precise and consistent contact without causing damage or wear. This gentleness is particularly crucial when dealing with delicate and valuable PCBs, as it eliminates the risk of accidental damage during testing.

The elastomeric connectors are engineered to provide just the right amount of pressure to establish a reliable electrical connection without overcomplicating the process. This precise actuation ensures that your PCBs are tested accurately every time, contributing to the overall quality and performance of your products.

20,000+ Cycles and Field Replaceability

Flexible Test Fixtures are not only about performance but also durability. These fixtures are rated at an impressive 20,000+ cycles, meaning they can withstand continuous, rigorous testing without signs of wear or performance degradation. This remarkable cycle rating underscores their longevity and value, making them a cost-effective choice for businesses looking to streamline their testing processes.

However, even the most durable components may require maintenance at some point. That’s where the field replaceability of these fixtures comes into play. When the time comes to replace a component, it’s a straightforward and quick process, taking just minutes to complete. This minimizes downtime and ensures that your testing processes continue running smoothly.

Decades of Experience in Custom Device Testing

One of the key factors that set Flexible Test Fixtures apart from the competition is the extensive design and manufacturing experience that the team behind to the table. With over 25 years of experience in custom device testing, the creators of these fixtures have a deep understanding of the unique requirements and challenges that various industries and applications present.

This wealth of experience allows for the creation of highly tailored solutions that can accommodate a wide range of testing scenarios. Whether you’re in the consumer electronics industry, aerospace, automotive, or any other sector, Flexible Test Fixtures have the adaptability and expertise to meet your specific needs.

Furthermore, the insights gained from years of working with different clients and industries have been instrumental in refining and perfecting the design of these fixtures. Each iteration has been informed by real-world challenges and customer feedback, resulting in a product that is not only cutting-edge but also thoroughly tested and trusted.

Conclusion

If you’re tired of dealing with the frustrations and limitations of traditional PCB test fixture designs, it’s time to consider Flexible Test Fixtures. They are a simple, reliable, and durable solution for your PCB testing needs, providing peace of mind and efficiency in your testing processes. With a 20,000+ cycle rating and the elimination of troublesome components like ZIF connectors and pogo pins, these fixtures are poised to revolutionize the way you approach PCB testing. Say goodbye to the old, error-prone methods and welcome the future of PCB testing with open arms. Your products and your customers will thank you.

By embracing Flexible Test Fixtures, you’re not just replacing outdated testing methods; you’re embracing a new era of reliability and efficiency in your PCB testing endeavors. With these fixtures, you can expect a dramatic reduction in testing errors and failures, leading to increased productivity and lower overall operational costs. Your team will appreciate the simplicity of the drop-in solution, while your bottom line will benefit from reduced downtime and maintenance expenses. Moreover, as your testing processes become more robust and dependable, your products will consistently meet and exceed quality standards, ultimately leaving a positive impression on your customers and enhancing your brand’s reputation for excellence.