How Automated Test Fixtures Can Enhance Your Test Setup

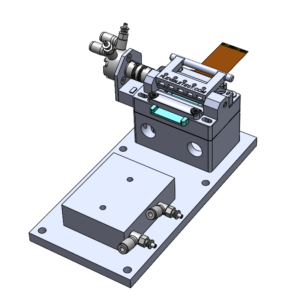

Pneumatically Automated FFC Test Fixture

In today’s dynamic electronics landscape, precision, efficiency, and reliability are paramount to achieving success. Meeting rigorous quality standards for your electronic components is not only crucial but also the key to thriving in this ever-evolving industry. This is where automated test fixtures step in as the driving force behind modern electronics testing. In this comprehensive guide, we delve into how Flexible Test is reshaping the industry with its versatile, customizable, and effortlessly integratable automated test fixtures.

The Significance of Automated Test Fixtures

In a world where electronics are rapidly evolving, the demand for precise, efficient, and reliable testing is higher than ever. Automated test fixtures have emerged as the solution to meet these demands. These fixtures are designed to seamlessly connect your Device Under Test (DUT) to your testing equipment, automating the testing process with precision. But what sets Flexible Test’s automated fixtures apart is their adaptability.

Typical Automated Test Fixtures: Their Importance and Common Failures

In the world of electronics testing, automated test fixtures play a pivotal role in ensuring the quality and reliability of electronic components. These fixtures are designed to seamlessly connect your Device Under Test (DUT) to your testing equipment, automating the testing process with precision and efficiency. However, despite their significance, automated test fixtures can experience failures that can disrupt testing processes. Understanding these typical failures is crucial for optimizing your testing setup.

Common Failures in Automated Test Fixtures

- Connector Failures: Connectors are the bridge between your DUT and the testing equipment. One common failure is connector wear and tear, leading to unreliable connections. Frequent plugging and unplugging can cause connectors to degrade over time, resulting in electrical or mechanical failures.

- Cable Failures: The cables used in automated test fixtures are susceptible to various issues, including signal degradation, insulation breakdown, or cable breakage. These cable failures can lead to inaccurate test results and increased downtime.

- Contact Pin Failures: Contact pins are responsible for establishing electrical connections between the DUT and the testing equipment. Over time, contact pins can experience wear, corrosion, or misalignment, causing intermittent or unreliable connections.

- Software and Control Failures: Automation control systems, including software and hardware, can fail due to software bugs, hardware malfunctions, or compatibility issues. These failures can result in testing errors and require time-consuming troubleshooting.

- Environmental Factors: Automated test fixtures are often used in various environmental conditions. Factors like temperature, humidity, and dust can impact the fixture’s performance and lead to potential failures.

Addressing Automated Test Fixture Failures

To overcome these common failures and ensure seamless testing processes, it’s essential to consider reliable solutions. Flexible Test has addressed these challenges by designing automated test fixtures that are equipped with field-replaceable components. This means that when failures occur, the affected components can be quickly replaced, minimizing downtime and keeping your testing process efficient.

Additionally, our fixtures are designed to endure harsh environmental conditions, ensuring reliability in various testing environments. Our automation controls are user-friendly, making it easy for you to connect the fixture to your testing setup and control the actuation process with precision.

Versatile Automation Options

At Flexible Test, we understand that different testing setups require different automation options. That’s why our fixtures can be automated by a variety of means, including pneumatic and electrical automation. This adaptability ensures that you can seamlessly integrate our fixtures into your existing setup, regardless of your automation preferences.

Field-Replaceable Components

One of the standout features of Flexible Test’s automated fixtures is the field-replaceable components. In the fast-paced world of electronics testing, time is of the essence. If a component fails or needs replacement, our fixtures are designed to make this process quick and straightforward. In a matter of minutes, you can replace a component, minimizing downtime, and ensuring that your testing process remains efficient and uninterrupted.

Simplified Incoming and Outgoing Testing

Automation doesn’t stop with the testing process; it extends to both incoming and outgoing testing. Flexible Test’s automated fixtures simplify these critical aspects of electronics testing. Whether you’re receiving components for testing or preparing them for distribution, our fixtures ensure a seamless and efficient process. This automation results in faster turnaround times and helps you maintain a competitive edge in the market.

Easy-to-Use Test Fixtures

Automation should not equate to complexity. We’ve designed our fixtures with usability in mind. Our easy-to-use test fixtures streamline the testing process, allowing you to achieve precision without the hassle. This user-friendly approach is essential in the fast-paced world of electronics, where every moment counts. We want to ensure that your testing process is as efficient as possible without compromising on accuracy.

Seamless Integration with Your Test Setup

Connecting the fixtures to your test setup is a breeze with our automation controls. Whether you choose pneumatic or electrical automation, you can effortlessly hook up the fixture to your testing equipment. We understand that time is a precious resource in electronics testing, and our fixtures are engineered to save you time and effort.

Control at Your Fingertips

In the world of electronics testing, control is paramount. With Flexible Test’s automated fixtures, control is at your fingertips. You can easily control the fixture actuation, ensuring that your testing process runs precisely as intended. This level of control empowers you to achieve consistent and reliable results, test after test.

The Future of Electronics Testing with Automated Fixtures

In a world where electronics continue to advance and become more intricate, the reliability and precision of testing are crucial. Flexible Test is at the forefront of innovation, dedicated to delivering state-of-the-art automated test fixtures that keep pace with these dynamic changes. By ensuring that your testing processes consistently meet stringent performance standards, we enable the development of cutting-edge electronics. From incoming and outgoing testing to precision testing processes, we’re here to provide the automation solutions that keep you ahead of the curve.

Conclusion

Join us in embracing the future of electronics testing with our versatile, field-replaceable, and easy-to-use automated fixtures. Let’s make your testing processes efficient, cost-effective, and reliable, one fixture at a time. Connect with Flexible Test and experience the next generation of automated test fixtures, revolutionizing the way you ensure quality in your electronic components.