The Advantages of Aluminum Test Fixtures by Flexible Test

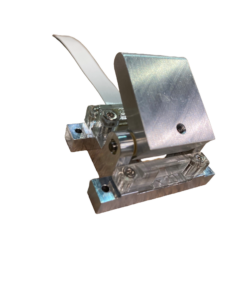

The choice of test fixtures can significantly impact the efficiency and reliability of the electronics testing process. As technology advances, so do the demands placed on testing equipment, especially when it comes to rugged support in tough test environments. This is where Flexible Test’s Aluminum Test Fixtures emerge as the unsung heroes, offering a robust solution designed to withstand the challenges of demanding testing environments.

Understanding the Need for Rugged Support

In the realm of electronics testing, environmental factors can often be unpredictable and harsh. From extreme temperatures to varying levels of humidity, traditional test fixtures may find it challenging to maintain consistency in such conditions. Aluminum Test Fixtures, however, stand out as a beacon of reliability. The choice of aluminum as a material is not arbitrary; it’s a strategic decision to provide rugged support that can endure the harshest testing environments. Let’s delve into the multifaceted benefits that make Aluminum Test Fixtures a game-changer in the world of electronics testing.

- 1. Rugged Durability

- Weathering the Storm

- Aluminum, known for its exceptional strength-to-weight ratio, is the backbone of our rugged test fixtures. Its inherent durability ensures that our fixtures can withstand not only the normal wear and tear of testing cycles but also the challenges posed by tough environmental conditions. Whether your testing environment involves temperature fluctuations, humidity variations, or exposure to corrosive substances, our Aluminum Test Fixtures provide a steadfast and durable support system.

- Weathering the Storm

- 2. Thermal Stability

- Keeping Cool Under Pressure

- Temperature fluctuations are a common concern in many testing environments. Aluminum’s excellent thermal conductivity ensures that our fixtures remain stable across a wide range of temperatures. This thermal stability not only safeguards the integrity of the fixtures but also contributes to the consistent and accurate performance of the testing equipment. Say goodbye to concerns about overheating or temperature-induced malfunctions – our Aluminum Test Fixtures keep cool under pressure.

- Keeping Cool Under Pressure

- 3. Corrosion Resistance

- A Shield Against Deterioration

- In challenging test environments, exposure to corrosive elements can be a silent threat to the longevity of test fixtures. Aluminum’s natural corrosion resistance acts as a shield, protecting our fixtures from deteriorating over time. This resistance to corrosion ensures that the fixtures maintain their structural integrity, providing a reliable platform for testing even in environments with corrosive agents.

- A Shield Against Deterioration

- 4. Lightweight Strength

- Maneuverability Without Compromise

- Despite its robustness, aluminum remains surprisingly lightweight. This characteristic is a boon for testing setups that require maneuverability and flexibility. Our Aluminum Test Fixtures strike the perfect balance between strength and weight, offering the rugged support needed without sacrificing ease of handling or the ability to adapt to different testing scenarios.

- Maneuverability Without Compromise

- 5. Enhanced Conductivity

- Efficient Electrical Pathways

- In electronics testing, the efficiency of electrical pathways is paramount. Aluminum’s conductivity ensures that our fixtures provide an efficient and reliable electrical pathway between the Device Under Test (DUT) and the testing equipment. This enhanced conductivity contributes to the accuracy of test results, making our Aluminum Test Fixtures a dependable choice for applications where precision is non-negotiable.

- Efficient Electrical Pathways

- 6. Modular Flexibility

- Tailoring Solutions to Your Needs

- Flexibility is at the core of our Aluminum Test Fixtures. Recognizing that different testing environments come with unique challenges, we offer modular designs that allow for customization. Need additional features or specific adjustments for your testing setup? Our Aluminum Test Fixtures can be tailored to meet your exact requirements, providing a versatile solution that adapts to the ever-evolving landscape of electronics testing.

- Tailoring Solutions to Your Needs

- 7. Drop-In Solution

- Streamlining Integration Effortlessly

- Our Aluminum Test Fixtures are not just durable; they are designed for seamless integration. The drop-in solution ensures that incorporating our fixtures into your existing testing setup is a hassle-free experience. Say goodbye to complex configurations and time-consuming adjustments. With Flexible Test, it’s about enhancing efficiency from the moment our Aluminum Test Fixtures are introduced into your testing environment.

- Streamlining Integration Effortlessly

- 8. High Cycle Count

- Endurance Beyond Expectations

- When it comes to testing, longevity matters. Our Aluminum Test Fixtures boast an impressive cycle count of 10,000 and beyond. This exceptional durability ensures that our fixtures can endure the demands of extensive testing cycles without compromising performance. Experience reliability that stands the test of time, providing consistent results test after test.

- Endurance Beyond Expectations

- 9. User-Friendly Design

- Intuitive Operation for Optimal Performance

- At Flexible Test, we understand the importance of user-friendly design in optimizing testing processes. Our Aluminum Test Fixtures are crafted with an intuitive design that simplifies operator tasks. From straightforward setup procedures to easy operation, our fixtures are engineered to enhance usability. Operators can focus on precision without unnecessary complexity, ensuring optimal performance in every testing scenario.

- Intuitive Operation for Optimal Performance

- 10. Field-Replaceable Components

- Minimizing Downtime

- In the world of testing, time is money. Our Aluminum Test Fixtures feature field-replaceable components, minimizing downtime and ensuring that your testing process remains efficient and uninterrupted. When maintenance is required, our fixtures are designed for quick and easy component replacement, allowing you to get back to testing without unnecessary delays.

- Minimizing Downtime

- 11. Precision Engineering

- Consistent and Accurate Results

- Precision is the cornerstone of effective testing. Our Aluminum Test Fixtures are the result of meticulous engineering, ensuring that they consistently deliver accurate results. From the stability of electrical pathways to the overall reliability of the fixture, each component is crafted with precision, contributing to the integrity of your testing processes.

- Consistent and Accurate Results

- 12. Cost-Effective Solution

- Long-Term Savings Without Compromise

- Investing in Flexible Test’s Aluminum Test Fixtures is not just about immediate benefits; it’s a cost-effective approach for the long term. The rugged durability, high cycle count, and ease of maintenance translate to lower long-term maintenance and replacement expenses. Make a smart investment that aligns with your budget while ensuring a robust testing environment.

- Long-Term Savings Without Compromise

Conclusion

Our Aluminum Test Fixtures are not merely components in a testing setup; they are strategic assets that elevate your operations. From drop-in integration to user-friendly operation, high cycle counts to precision engineering, Flexible Test’s Aluminum Test Fixtures redefine the standards of durability, reliability, and adaptability in the world of electronics testing.

Choose Aluminum Test Fixtures by Flexible Test and empower your testing environment with a solution that goes beyond expectations, delivering results that withstand the challenges of the ever-evolving testing landscape.

Contact us today!